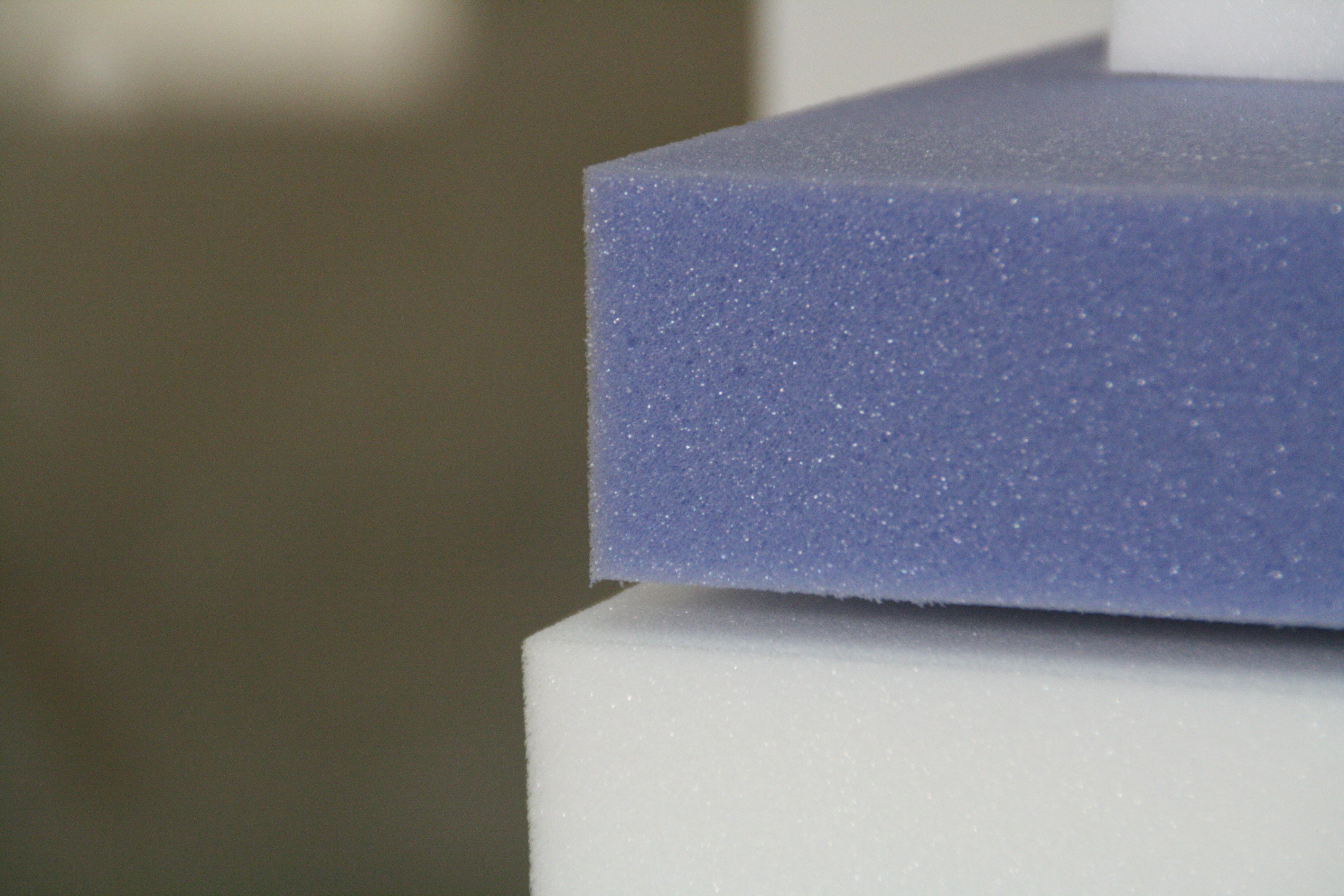

Contact BS Flexible Polyurethane Foam

Interplasp currently works with five ranges of flexible polyurethane foam and one of them is Contact BS. Contact BS foam is characterized by a rigorous manufacturing system that allows to control all the properties and, thus, to reach a certain degree of comfort. It has been created to provide high quality in all products aimed at improving our life quality. Its different densities and firmness makes it have many applications in the rest sector. In addition, this material has been subjected to fire behavior tests based on “British Legislation Consumer Protection”, standard BS 5852, which deals with the flammability of upholstered furniture. The results have been satisfactory giving him fire-retardant qualities.

PHYSICAL PROPERTIES:

Density – ISO 845

C.L.D – ISO 3386

I.L.D – ISO 2439

Permanent deformation 75% – ISO 1856

Resilence – ISO 8307

Tensile strength – ISO 1798