La auditoría realizada por AENOR certifica a Interplasp como la primera empresa del sector en cumplir los requisitos para la obtención de los reconocimientos de Huella de Carbono y Residuo Cero.

La Certificación de Huella de Carbono es la base para la certificación como una empresa neutral en emisiones de carbono y permite a las compañías participar en iniciativas internacionales que publiquen o determinen los niveles de emisión de carbono.

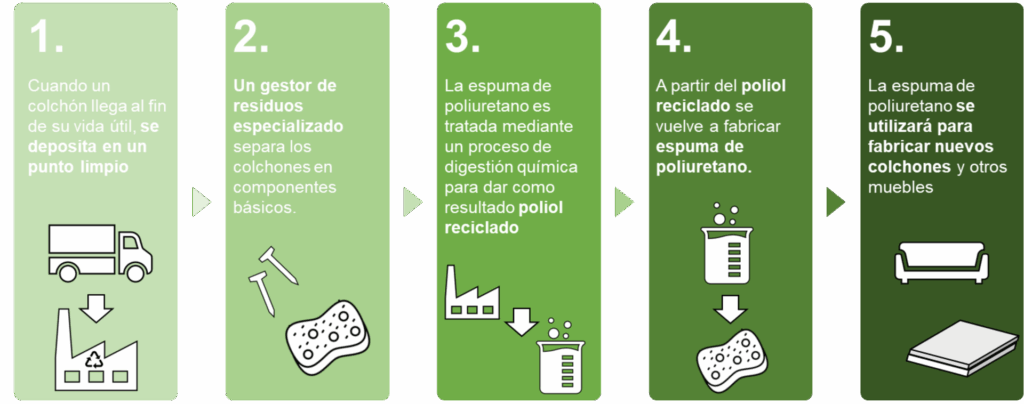

El modelo de Economía Circular persigue invertir la pirámide actual de la gestión de residuos, maximizando las acciones de prevención y valorización de residuos (reutilización, reciclado o valorización energética). La certificación Residuo Cero se enmarca en la línea de actuaciones de la OCDE, PNUMA, G20, PEMAR, Unión Europea y España en lo relativo a Economía Circular. El certificado de AENOR Residuo Cero reconoce a aquellas organizaciones que valorizan las distintas fracciones de residuos que generan, dentro del alcance definido, evitando que tengan como destino final la eliminación en vertedero.

La obtención de ambos certificados demuestra el compromiso con la excelencia de Interplasp y la firme apuesta por la sostenibilidad y la reducción del impacto medioambiental de la organización.